CMMS systems are revolutionizing maintenance strategies across industries. Imagine a world where equipment downtime is minimized, maintenance costs are controlled, and your entire facility runs like a well-oiled machine. This guide delves into the intricacies of CMMS, from foundational concepts to advanced implementations, providing a comprehensive overview of its power and potential.

This exploration will cover everything from defining CMMS and its various types, to the critical steps in implementation and integration with other business systems. We’ll also look at how CMMS data powers insightful reporting, and how it can reshape maintenance strategies, improving overall efficiency and profitability.

Defining CMMS

CMMS, or Computerized Maintenance Management System, is basically a digital tool that helps companies keep their equipment running smoothly. Think of it as a super-organized planner for all things maintenance. Instead of relying on spreadsheets and sticky notes, a CMMS lets you track everything from scheduled repairs to emergency fixes, all in one centralized system.

A CMMS streamlines the maintenance process by providing a comprehensive platform for managing equipment, tasks, and personnel. This helps companies optimize their maintenance strategies, reduce downtime, and minimize costs associated with repairs and replacements. It’s essentially a digital hub for all things maintenance-related, ensuring that everything is documented, tracked, and readily accessible.

Key Functionalities of a CMMS

CMMS software boasts a wide range of features that automate and optimize maintenance procedures. These functions are crucial for effective asset management.

- Work Order Management: CMMS systems enable the creation, tracking, and completion of work orders. This feature facilitates efficient workflow management by providing a centralized platform to schedule, assign, and monitor maintenance tasks. This helps prevent missed tasks and ensure timely completion.

- Inventory Management: A crucial function is the management of spare parts and supplies. This allows for accurate tracking of inventory levels, which prevents stockouts and optimizes resource allocation.

- Equipment Management: CMMS systems can store detailed information about each piece of equipment, including its specifications, maintenance history, and location. This helps in making informed decisions regarding equipment upgrades, replacements, or repairs.

- Reporting and Analytics: CMMS provides valuable data and reports on maintenance activities, equipment performance, and costs. These reports are invaluable for identifying trends, improving efficiency, and optimizing maintenance strategies.

Types of CMMS Software

Different CMMS solutions cater to various needs and industries. The best choice often depends on the specific requirements of the organization.

- General-purpose CMMS: These systems provide a broad range of functionalities and are suitable for a wide range of industries. They typically offer features like work order management, inventory control, and reporting.

- Industry-specific CMMS: Some CMMS software are tailored to particular industries, such as manufacturing, healthcare, or utilities. These systems may include industry-specific functionalities and regulations.

- Modular CMMS: These systems are designed with flexibility in mind, allowing companies to select and implement the modules that best meet their needs. This can be more cost-effective for organizations with specific maintenance requirements.

CMMS Deployment Models

The way a CMMS is deployed—cloud, on-premise, or hybrid—significantly impacts its functionality and cost.

- Cloud-based CMMS: These systems are hosted on remote servers, accessible through the internet. This offers scalability, flexibility, and reduced upfront costs. Cloud CMMS systems are generally more user-friendly and often provide real-time data.

- On-premise CMMS: This involves installing the CMMS software on the company’s own servers. This provides more control and security but often comes with higher upfront costs and requires IT expertise for maintenance.

- Hybrid CMMS: This combines cloud and on-premise features, allowing for a customized solution. This approach offers flexibility, enabling companies to choose which aspects of the system are cloud-based and which are on-premise.

Comparison of Deployment Models

| Deployment Model | Pros | Cons |

|---|---|---|

| Cloud | Scalability, accessibility, reduced upfront costs, often real-time data, easy updates | Internet dependency, potential security concerns, vendor lock-in |

| On-premise | Greater control over data, enhanced security, customization potential | High upfront costs, maintenance responsibility, limited scalability |

| Hybrid | Flexibility to combine best features of cloud and on-premise, better security options | Can be complex to manage, requires expertise to integrate different systems |

CMMS Implementation

Implementing a CMMS is a significant undertaking, but a well-planned and executed implementation can yield substantial benefits for any organization. Careful consideration of pre-implementation steps, data migration strategies, and user training is crucial for successful adoption and long-term ROI. This process is not a one-size-fits-all approach; each organization needs to tailor its plan to its specific needs and context.

The key to a successful CMMS implementation lies in understanding the unique needs of your organization and aligning the CMMS to support those needs. This means identifying pain points in your current maintenance processes, evaluating potential CMMS solutions, and ensuring the system is scalable to meet future growth.

Pre-Implementation Planning Stages

Proper planning before implementing a CMMS is essential for a smooth transition. This involves defining clear objectives, identifying key users, and outlining a realistic timeline. Thorough research and due diligence in selecting the right CMMS vendor are critical for long-term success. A comprehensive project plan should include detailed timelines, budget allocations, and resource assignments. Understanding existing workflows and identifying potential roadblocks is paramount. Detailed documentation of existing processes is crucial for a seamless migration.

Data Migration from Legacy Systems

Migrating data from existing systems to a new CMMS is a critical step. A structured approach is necessary to minimize disruption and ensure data integrity. A phased approach to data migration is often the most effective strategy. This involves carefully mapping the fields from the legacy system to the CMMS. Data validation checks should be implemented to ensure accuracy and completeness. Regular testing and quality control are vital to catch and correct any errors early in the process. Backup and recovery procedures are paramount to mitigate any potential data loss.

User Training and Adoption

User training and adoption are critical to ensuring the long-term success of a CMMS. Effective training programs equip users with the skills and knowledge necessary to use the system effectively. Training should be tailored to different user roles, ensuring each user understands their specific responsibilities within the system. A combination of classroom instruction, hands-on workshops, and online resources can create a comprehensive training experience. The training should cover not just the technical aspects of the system but also the strategic benefits and how it improves efficiency.

Step-by-Step User Training Procedures

- Initial Overview: Introduce the CMMS system, its key features, and benefits. Highlight the ways it will improve efficiency and reduce costs. Explain the overall system architecture and the workflow.

- Module-Specific Training: Break down the CMMS into modules (e.g., work orders, preventive maintenance, inventory). Provide hands-on exercises and practical examples for each module.

- Role-Based Training: Tailor training to different user roles (e.g., maintenance technicians, supervisors, administrators). Demonstrate how each role can leverage the system to achieve their specific tasks.

- Troubleshooting and Support: Address potential issues and provide resources for users to resolve common problems independently. Establish clear communication channels for support requests.

- Post-Training Reinforcement: Follow-up training sessions and ongoing support are crucial for successful adoption. Regular check-ins and feedback mechanisms ensure users stay engaged and proficient in using the system.

CMMS Features and Benefits

CMMS software, or Computerized Maintenance Management Systems, is more than just a fancy name. It’s a powerful tool that streamlines maintenance processes, improves efficiency, and ultimately saves your company money. A well-implemented CMMS provides a centralized hub for all maintenance-related data, empowering informed decisions and optimized resource allocation.

This section delves into the key features and benefits of a CMMS, highlighting its impact on preventive and predictive maintenance, downtime reduction, and its value across various industries. We’ll examine how a CMMS helps organizations stay ahead of the curve in maintaining their assets and operations.

Core Features of an Effective CMMS

A robust CMMS encompasses several critical features that enable its effectiveness. These features are designed to collect, store, and analyze data to provide a comprehensive view of maintenance activities. A strong CMMS system facilitates improved efficiency and better decision-making across the board.

- Asset Management: This feature allows for the detailed tracking of all equipment, from basic specifications to maintenance history. This crucial data is essential for preventive maintenance scheduling and for identifying potential problems before they arise. For example, knowing the age and usage patterns of a machine helps predict when it might need maintenance or replacement.

- Work Order Management: This capability facilitates the creation, assignment, and tracking of work orders, ensuring timely completion and accurate documentation. This streamlined process reduces the likelihood of missed maintenance tasks and helps maintain transparency in the workflow.

- Inventory Management: This feature enables efficient tracking of spare parts and supplies, preventing stockouts and optimizing resource allocation. Knowing exactly what spare parts are available, and where, is crucial for reducing downtime and minimizing the cost of emergency replacements.

- Reporting and Analytics: A good CMMS provides insightful reports on maintenance activities, equipment performance, and overall operational efficiency. These reports are valuable tools for identifying trends, improving strategies, and enhancing decision-making.

Benefits of a CMMS for Preventive Maintenance

Implementing a CMMS for preventive maintenance leads to substantial advantages. By proactively scheduling maintenance tasks based on predefined schedules and equipment history, organizations can avoid costly breakdowns and extend the lifespan of their assets.

- Reduced Downtime: Proactive maintenance schedules minimize unexpected equipment failures, which directly translates to reduced downtime. This reduction in downtime directly affects production output and profitability.

- Extended Equipment Lifespan: Consistent preventive maintenance helps prevent premature wear and tear on equipment, extending its operational life and minimizing replacement costs.

- Cost Savings: By avoiding costly breakdowns and repairs, preventive maintenance significantly reduces maintenance expenses in the long run. This is a key benefit in minimizing unexpected costs.

Benefits of a CMMS for Predictive Maintenance

Predictive maintenance leverages data analysis to anticipate potential equipment failures, allowing for timely interventions and preventing costly breakdowns.

- Proactive Problem Solving: Predictive maintenance enables organizations to address potential issues before they impact operations, preventing unplanned downtime and maximizing operational efficiency. By anticipating problems, you can avoid the costly repairs that arise from sudden equipment failure.

- Optimized Maintenance Schedules: Predictive analytics allows for the scheduling of maintenance tasks based on actual equipment needs, rather than fixed schedules. This approach ensures that resources are used effectively and efficiently.

- Improved Equipment Reliability: By identifying potential failures in advance, predictive maintenance ensures that equipment operates reliably and consistently, leading to increased uptime and productivity.

Impact of CMMS on Reducing Downtime

A CMMS significantly impacts downtime reduction. By streamlining maintenance tasks, improving communication, and providing real-time data, a CMMS allows organizations to react quickly to equipment failures and minimize disruptions to operations.

- Faster Response Times: A CMMS centralizes information, making it easier for maintenance teams to quickly identify and address equipment issues. This feature is crucial in minimizing the duration of any downtime.

- Improved Communication: CMMS systems enhance communication between different departments, ensuring that everyone is aware of maintenance schedules, issues, and progress. This improved communication streamlines the process.

- Reduced Emergency Repairs: By implementing preventive and predictive maintenance strategies, a CMMS helps to minimize the need for emergency repairs, saving significant time and money.

CMMS Benefits Across Industries

The benefits of a CMMS extend across various industries. The specific advantages will vary depending on the unique needs and challenges of each industry.

| Feature | Benefit |

|---|---|

| Asset Management | Improved tracking of equipment and maintenance history |

| Work Order Management | Streamlined workflow and improved communication |

| Inventory Management | Optimized resource allocation and reduced stockouts |

| Reporting and Analytics | Data-driven insights for improved decision-making |

CMMS Integration with Other Systems

CMMS systems aren’t islands. They thrive when connected to the broader ecosystem of your business. Integrating a CMMS with other enterprise systems unlocks significant benefits, boosting efficiency and data accuracy. This integration streamlines workflows, allowing for a more holistic view of maintenance and operations.

Importance of Integration

Integration between a CMMS and other enterprise systems is crucial for several reasons. It creates a unified data source, eliminating data silos and improving data accuracy. This interconnectedness allows for real-time updates and visibility across departments, enabling better decision-making and resource allocation. Moreover, seamless integration minimizes manual data entry, reducing errors and freeing up personnel for more strategic tasks.

Examples of Integrable Systems

Integrating a CMMS with other business systems provides a more comprehensive view of your operations. Several systems can be effectively integrated with a CMMS, enhancing the overall efficiency and effectiveness of your maintenance programs. Examples include:

- Enterprise Resource Planning (ERP) Systems: ERP systems manage core business processes, such as finance, inventory, and procurement. Integration with a CMMS allows for better inventory management of spare parts, linking purchasing decisions to maintenance needs, and automating expense tracking related to maintenance activities.

- Customer Relationship Management (CRM) Systems: CMMS integration with CRM allows for better tracking of maintenance requests and service issues associated with customers. This facilitates better customer service and potentially identifies patterns in maintenance requests, leading to proactive maintenance strategies.

- Scheduling Systems: Integration with scheduling systems directly impacts the efficiency of maintenance scheduling and dispatching. This integration ensures that maintenance tasks are scheduled and executed effectively, reducing downtime and optimizing resource allocation.

CMMS Integration with a Scheduling System

A well-integrated CMMS and scheduling system significantly enhances the scheduling and dispatching of maintenance tasks. The CMMS can automatically generate work orders based on predefined schedules or alerts, and the scheduling system can manage the allocation of technicians and equipment to those orders. This automated process minimizes scheduling conflicts, ensures efficient use of resources, and minimizes downtime. The CMMS can also track the progress of scheduled maintenance tasks, providing real-time visibility into the status of maintenance activities.

Improving Data Accuracy and Consistency

Integration ensures data consistency by eliminating manual data entry and the risk of errors associated with transferring data between systems. This centralized data repository leads to a more accurate and comprehensive understanding of maintenance activities. Accurate data allows for better predictive maintenance strategies and more precise resource allocation.

Streamlining Workflows

Integration with other systems automates many tasks, streamlining workflows across departments. For example, automated notifications and updates across the system can reduce manual communication and improve efficiency. By reducing the manual effort required to update information across various systems, the integration process improves operational efficiency and reduces errors.

Common CMMS Integrations

The following table Artikels some common integrations for a CMMS, highlighting the potential benefits:

| System | Integration Details |

|---|---|

| ERP System | Improved inventory management of spare parts, automated procurement of materials, and better tracking of maintenance costs. |

| CRM System | Better tracking of maintenance requests from customers, proactive maintenance based on customer needs, and enhanced customer service. |

| Scheduling System | Automated scheduling of maintenance tasks, optimized technician and equipment allocation, and reduced scheduling conflicts. |

| Billing System | Automated billing and invoicing for maintenance services, reducing manual work and improving accuracy. |

CMMS Data Management and Reporting

CMMS systems aren’t just about tracking maintenance tasks; they’re about extracting actionable insights from the data. Effective data management and reporting are crucial for optimizing maintenance strategies, identifying trends, and ultimately, saving money. A well-designed CMMS allows you to get a 360-degree view of your maintenance operations, enabling proactive problem-solving and informed decision-making.

CMMS software excels at organizing and analyzing maintenance data, leading to improved efficiency and cost savings. The system’s ability to generate reports, tailored to specific needs, allows for deeper insights into maintenance performance. These reports are essential tools for identifying bottlenecks, predicting future issues, and ensuring compliance.

How CMMS Manages Maintenance Data Effectively

CMMS systems employ robust databases to store and manage maintenance data meticulously. This data encompasses details like equipment history, maintenance schedules, work orders, and asset information. The structured format allows for easy retrieval, analysis, and reporting. Sophisticated algorithms and data validation processes are often built into the software, ensuring data accuracy and reliability. This structured approach facilitates comprehensive tracking of maintenance activities, enabling effective management of maintenance data.

Types of Reports Generated by CMMS Software

CMMS software generates a wide range of reports, catering to various reporting needs. These reports offer insights into maintenance effectiveness, equipment performance, and overall operational efficiency. They are not just summaries; they are data-driven tools that inform strategic decisions.

- Work Order Reports: These reports detail the status of individual work orders, including completion times, costs, and personnel involved. They provide a comprehensive overview of the maintenance work performed, enabling efficient tracking and management of maintenance activities.

- Preventive Maintenance Reports: These reports showcase the adherence to preventive maintenance schedules, highlighting any deviations or missed opportunities. This information is critical for identifying potential problems before they escalate into major issues, thereby ensuring optimal equipment performance.

- Equipment Performance Reports: These reports analyze the performance of individual equipment assets, including uptime, downtime, and maintenance costs. This helps in pinpointing assets that require more attention or preventative maintenance, leading to optimized asset management.

- Financial Reports: These reports provide insights into the financial impact of maintenance activities. This includes costs associated with maintenance tasks, labor, and materials, aiding in budgeting and cost control.

- Maintenance Cost Reports: These reports provide a detailed breakdown of maintenance costs over various periods, enabling effective cost analysis and budget management. They also aid in identifying areas where maintenance costs can be reduced.

Key Performance Indicators (KPIs) Tracked by CMMS

CMMS systems allow for the tracking of crucial Key Performance Indicators (KPIs) related to maintenance operations. These KPIs provide a quantitative measure of performance, enabling comparison across different periods and departments.

- Mean Time Between Failures (MTBF): This metric indicates the average time between equipment failures. A higher MTBF signifies more reliable equipment and improved maintenance strategies.

- Mean Time to Repair (MTTR): This metric measures the average time taken to repair equipment after a failure. A lower MTTR indicates more efficient repair processes.

- Maintenance Cost per Unit: This KPI tracks the cost of maintenance per unit of production or service. It aids in identifying areas for cost optimization.

- Preventive Maintenance Compliance Rate: This KPI measures the adherence to scheduled preventive maintenance tasks. A high compliance rate indicates effective maintenance scheduling and planning.

Creating Customized Reports from CMMS Data

CMMS systems often allow for the creation of custom reports tailored to specific needs. Users can select specific fields, date ranges, and criteria to generate reports that directly address their requirements. This level of customization ensures the reports are truly valuable and insightful.

Data Security and Compliance in a CMMS Environment

Protecting the sensitive maintenance data within a CMMS is paramount. Robust security measures, such as access controls and encryption, are vital to safeguard the integrity and confidentiality of the information. Compliance with relevant regulations is equally important. Ensuring data security and compliance helps maintain the integrity of data and safeguards against potential breaches.

Common CMMS Reports and Their Purposes

| Report Type | Purpose |

|---|---|

| Work Order Report | Tracks individual work order status, costs, and personnel |

| Preventive Maintenance Report | Monitors adherence to preventive maintenance schedules |

| Equipment Performance Report | Analyzes equipment uptime, downtime, and maintenance costs |

| Financial Report | Provides insights into the financial impact of maintenance |

| Maintenance Cost Report | Details maintenance costs over specific periods |

CMMS and Maintenance Strategies

CMMS software isn’t just about tracking equipment; it’s a powerful tool for optimizing your entire maintenance process. By integrating with various maintenance strategies, a CMMS helps businesses streamline operations, reduce downtime, and improve overall efficiency. It allows for proactive planning and execution, leading to cost savings and a more reliable facility.

A well-implemented CMMS system can significantly impact maintenance strategies. It provides a centralized repository for all maintenance-related data, enabling a more informed and data-driven approach to maintenance scheduling and execution. This, in turn, allows for the development of more effective maintenance plans and ultimately, better asset management.

CMMS Support for Various Maintenance Strategies

CMMS systems support various maintenance strategies, empowering businesses to tailor their approach to specific needs and equipment. Different strategies, from preventative to predictive, require varying levels of data collection and analysis. CMMS excels at handling this complexity, enabling companies to move beyond reactive maintenance to more proactive and cost-effective solutions.

Impact on Optimizing Maintenance Schedules

CMMS systems provide a centralized platform for tracking maintenance schedules and work orders. This allows for better coordination and prioritization of tasks, resulting in optimized maintenance schedules. By analyzing historical data, CMMS can predict potential equipment failures and schedule maintenance proactively, reducing unplanned downtime and improving operational efficiency. For example, a CMMS can identify patterns in equipment failures that suggest a need for more frequent maintenance, or perhaps a change in maintenance procedures, optimizing future schedules.

Managing Work Orders Efficiently

CMMS facilitates efficient work order management by providing a standardized process for tracking and managing requests. From initial submission to completion, each step of the work order lifecycle can be monitored and controlled through the CMMS. This ensures that tasks are completed on time and within budget, minimizing delays and maximizing productivity. A well-designed work order system within a CMMS helps ensure transparency, accountability, and a clear overview of all maintenance activities.

Role in Improving Asset Management

CMMS plays a vital role in improving asset management by providing a centralized database of asset information. This includes details like equipment history, maintenance records, and location. This comprehensive data allows for better tracking of asset performance and helps in making informed decisions regarding asset replacement or upgrades. A strong asset management component of a CMMS system can identify potential issues and provide valuable data for future budgeting and capital expenditure decisions.

Maintenance Strategies Supported by a CMMS

A CMMS supports a variety of maintenance strategies, enabling businesses to tailor their approach to specific equipment and operational needs. These strategies can be categorized into various types.

- Preventative Maintenance: A CMMS allows for scheduling preventative maintenance tasks based on predetermined intervals or usage patterns. This proactive approach helps prevent breakdowns and minimizes downtime. Examples include routine lubrication, inspections, and cleaning of equipment. By incorporating preventative maintenance into a CMMS, you are actively ensuring the continued performance and reliability of your equipment.

- Predictive Maintenance: CMMS systems are invaluable for predictive maintenance by enabling the analysis of historical data to predict potential equipment failures. By identifying patterns and trends in equipment performance, a CMMS can proactively schedule maintenance before failures occur. This allows businesses to minimize downtime and optimize maintenance costs. An example is using sensor data to detect early signs of equipment wear and tear.

- Corrective Maintenance: CMMS systems track and manage corrective maintenance requests, ensuring timely resolution of equipment failures. This includes recording the cause of the failure, the actions taken, and the materials used for repair, allowing for future analysis and improvements. CMMS ensures that corrective actions are properly documented and tracked.

- Condition-Based Maintenance: CMMS supports condition-based maintenance by monitoring equipment health through various sensors and data points. Based on this real-time data, maintenance can be scheduled as needed, optimizing the equipment’s lifespan and minimizing unexpected breakdowns. This data-driven approach ensures equipment operates within optimal conditions.

CMMS Selection and Evaluation

Choosing the right CMMS is crucial for a smooth implementation and maximizing its benefits. A poorly chosen system can lead to wasted resources, frustrating user experiences, and ultimately, hinder maintenance effectiveness. Careful consideration of factors like budget, features, and scalability is essential to avoid costly mistakes down the line.

Selecting a CMMS isn’t just about finding the cheapest option; it’s about finding a solution that aligns with your specific needs and long-term goals. This involves a thorough evaluation process, considering the unique characteristics of your organization, including its size, industry, and existing maintenance procedures. This careful selection process can significantly impact the ROI and overall success of your CMMS deployment.

Factors to Consider When Selecting a CMMS

Several key factors should be considered when evaluating potential CMMS solutions. These factors influence the system’s functionality, usability, and overall fit within your organization.

- Budget: Determining a realistic budget is paramount. Consider not only the initial software cost but also ongoing expenses such as maintenance, training, and potential upgrades. It’s important to factor in the cost of data migration if you have existing maintenance records.

- Scalability: A crucial factor is whether the system can adapt to future growth. Consider how the CMMS can accommodate increasing asset counts, personnel, and complexity in maintenance tasks. A system that can expand with your business is crucial for long-term success.

- Integration Needs: Identify your organization’s existing systems, such as ERP, accounting, or inventory management. Assess the need for seamless integration with these systems to ensure data flow and avoid redundant processes. Ensure the CMMS can connect to your current infrastructure, minimizing disruption and data loss.

- User-Friendliness: Evaluate the system’s ease of use for different user roles. A user-friendly interface will reduce training time and increase adoption rates. Consider the training resources and support offered by the vendor, as this can greatly impact user satisfaction.

- Vendor Reputation and Support: Research the vendor’s reputation, experience, and support capabilities. Look for vendors with a proven track record and strong customer service. Thorough vendor research is key to ensuring reliable support when issues arise.

Criteria for Evaluating CMMS Vendors

Evaluating vendors involves assessing their capabilities and commitment to providing a quality product.

- Experience and Industry Knowledge: Evaluate the vendor’s experience in your industry and with similar organizations. Look for expertise in managing specific maintenance challenges relevant to your industry.

- Security Measures: Ensure the CMMS adheres to industry security standards and has robust data protection measures in place. A secure system is essential for safeguarding sensitive maintenance data.

- Training and Support: Assess the vendor’s training programs and support services. Look for resources such as documentation, online tutorials, and dedicated support staff to assist users.

- Customer Testimonials and Reviews: Examine customer testimonials and reviews to understand the vendor’s reputation and the experiences of other users. Look for reviews from organizations of similar size and needs to your own.

CMMS Software Evaluation Checklist

This checklist helps structure the evaluation process for CMMS software options.

- Functionality: Verify that the software supports your specific maintenance processes and workflows. Does the software allow for the capture of work orders, inventory management, and reporting?

- User Interface: Assess the ease of use and navigation for different user roles. Is the software intuitive and easy to learn?

- Integration Capabilities: Ensure the software can integrate with your existing systems. Can the CMMS seamlessly exchange data with other applications?

- Scalability: Confirm that the software can adapt to your future growth. Will it accommodate increasing asset counts and complexity in maintenance tasks?

- Support and Documentation: Evaluate the vendor’s support resources and documentation. Are there readily available tutorials, FAQs, and dedicated support staff?

CMMS Software Comparison Template

This template helps organize the comparison of different CMMS software options.

| Software | Ease of Use | Integration Capabilities | Reporting Features | Pricing | Customer Support |

|---|---|---|---|---|---|

| Software A | Good | Excellent | Comprehensive | $10,000/year | Responsive |

| Software B | Fair | Average | Basic | $5,000/year | Limited |

| Software C | Excellent | Excellent | Advanced | $15,000/year | Exceptional |

CMMS Use Cases and Examples

CMMS systems aren’t just for big factories anymore. They’re powerful tools for any organization needing to manage assets and maintenance effectively, from tiny startups to massive healthcare systems. This section dives into real-world examples across various industries, showing how CMMS can improve everything from equipment uptime to overall maintenance performance.

CMMS implementation goes beyond simply tracking repairs. It’s about creating a proactive approach to maintenance, enabling organizations to anticipate problems before they impact operations. By centralizing data and providing actionable insights, CMMS fosters a culture of preventative maintenance, ultimately boosting efficiency and reducing costs.

CMMS in Manufacturing

Manufacturing facilities often have complex equipment networks. A CMMS helps track the maintenance history of each piece of equipment, from routine checks to major overhauls. This data allows for better scheduling of maintenance tasks, minimizing downtime and maximizing equipment lifespan. Predictive maintenance capabilities, often integrated into CMMS platforms, further enhance this by analyzing patterns and alerting on potential failures. This can be invaluable in preventing costly unexpected breakdowns.

CMMS in Healthcare

Healthcare facilities face unique challenges, including stringent regulatory requirements and the need for meticulous record-keeping. CMMS solutions in healthcare can manage the maintenance of medical equipment, ensuring it’s functioning correctly and compliant with regulations. This includes tracking sterilization cycles, equipment calibrations, and preventative maintenance schedules for everything from MRI machines to patient beds.

CMMS in Retail

Retail environments require efficient and reliable operations to keep stores running smoothly. CMMS systems in retail settings can track the maintenance of HVAC systems, lighting fixtures, security cameras, and other equipment. Data analysis from CMMS can identify recurring maintenance issues, enabling proactive solutions. This approach optimizes operational efficiency, minimizing downtime and maximizing revenue potential.

Improving Equipment Uptime with CMMS

CMMS solutions significantly improve equipment uptime by centralizing maintenance data and providing a platform for proactive maintenance scheduling. Detailed historical records allow for the identification of recurring issues and the implementation of preventative maintenance strategies. Predictive maintenance capabilities are increasingly common, helping anticipate potential failures and schedule repairs before they impact operations. This results in less downtime, higher operational efficiency, and improved overall profitability.

Enhancing Maintenance Performance with CMMS

CMMS enhances maintenance performance through a structured approach to tasks. By standardizing procedures and tracking all maintenance activities, CMMS systems empower technicians with detailed information. This leads to more efficient and effective repairs, minimizing errors and maximizing repair time. Performance dashboards and reporting features provide clear insights into maintenance trends, enabling proactive adjustments and continuous improvement.

CMMS Implementation Examples in Different Facility Environments

A manufacturing plant using a CMMS might track equipment usage, maintenance schedules, and repair history for machinery across multiple production lines. A healthcare facility could leverage CMMS to manage maintenance for medical equipment, ensuring compliance with regulatory standards. A retail store could utilize CMMS to schedule and track the maintenance of HVAC systems, ensuring customer comfort and store operations. These examples illustrate the adaptability of CMMS across various facility types.

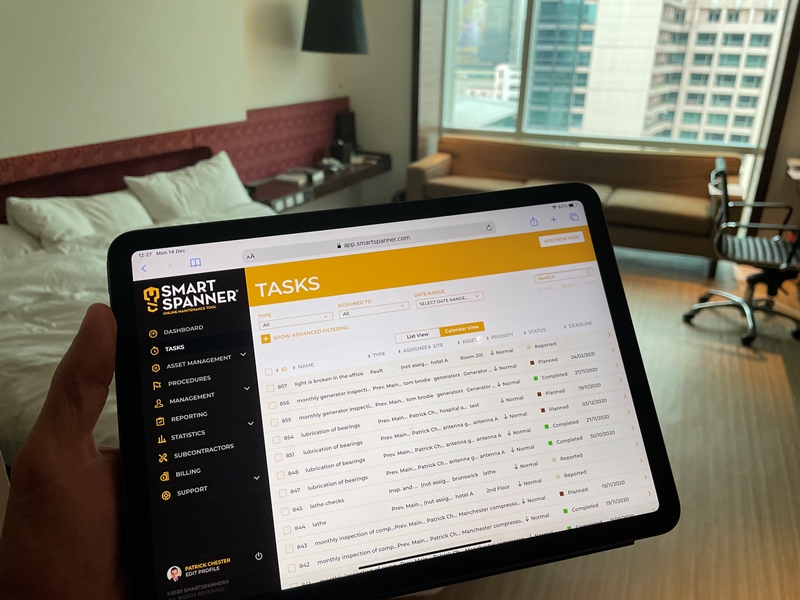

Visual Representation of CMMS Use in a Facility

Imagine a large warehouse with numerous pieces of equipment. A CMMS system, visualized as a central dashboard, displays real-time data on the status of each piece of equipment. Color-coded indicators highlight equipment needing attention, maintenance schedules, and repair history. Maintenance personnel can easily access this information through mobile devices, allowing for efficient task management.

Example: A red light on the dashboard indicates a piece of equipment requiring immediate attention, providing a visual cue for maintenance personnel.

Outcome Summary

In conclusion, a robust CMMS isn’t just a software program; it’s a strategic investment in your facility’s future. By understanding its capabilities, implementation strategies, and integrations, you can leverage CMMS to maximize uptime, reduce costs, and ultimately optimize your maintenance processes. The benefits are undeniable; from streamlined workflows to predictive maintenance, CMMS empowers you to proactively manage your assets and achieve operational excellence.