Hey, peeps! Inventory management is crucial for any biz, big or small. Imagine having a super organized system where you know exactly what you’ve got, where it is, and how much you need. That’s the magic of a good inventory management system! It’s like having a digital superhero, keeping track of everything from stock levels to sales reports. Ready to level up your biz game?

This comprehensive guide breaks down the ins and outs of inventory management systems, from the basics to advanced strategies. We’ll explore different types of systems, their key functions, and how to choose the right one for your needs. We’ll also look at the challenges, so you can be prepared. Get ready to optimize your inventory and unlock a whole new level of efficiency!

Introduction to Inventory Management Systems

Inventory management systems are crucial for businesses of all sizes to efficiently track, manage, and control their stock levels. Effective inventory management minimizes storage costs, reduces the risk of stockouts or overstocking, and ensures timely product delivery to customers. These systems play a vital role in optimizing profitability and maintaining a competitive edge in today’s dynamic market.

Accurate inventory tracking and control are fundamental to business success. By meticulously managing stock levels, businesses can reduce storage costs, minimize the risk of stockouts, and avoid the financial burden of excess inventory. Efficient inventory management also enables timely delivery of products to customers, boosting customer satisfaction and loyalty.

Definition of Inventory Management Systems

Inventory management systems are software-based or manual tools designed to track and manage inventory levels, costs, and locations. They automate the process of ordering, receiving, storing, and shipping products, providing real-time visibility into the entire inventory lifecycle. This enables businesses to optimize stock levels, minimize waste, and improve overall operational efficiency.

Fundamental Principles of Effective Inventory Management

Effective inventory management hinges on several key principles. Forecasting demand accurately is crucial, enabling businesses to anticipate future needs and order stock proactively. Maintaining optimal stock levels is essential to avoid stockouts, which can disrupt operations and lead to lost sales, while avoiding overstocking to mitigate storage costs and potential obsolescence. Implementing efficient order fulfillment processes is equally important to ensure timely delivery of products to customers, improving customer satisfaction. Finally, continuous monitoring and analysis of inventory performance are vital for identifying areas for improvement and adapting strategies to changing market demands.

Types of Inventory Management Systems

Different inventory management systems cater to varying business needs and complexities. Perpetual inventory systems track inventory levels in real-time, updating records with every transaction. Periodic inventory systems, on the other hand, count inventory periodically, often at the end of a specific period, to determine the quantity on hand. Choosing the appropriate system depends on the scale of operations, industry specifics, and technological resources available.

Examples of Industries Relying on Inventory Management Systems

Many industries heavily rely on inventory management systems. Retailers, wholesalers, and manufacturers use these systems to manage their stock effectively. Pharmaceutical companies need these systems to maintain strict quality control and track expiration dates. E-commerce businesses rely on them to fulfill orders rapidly and accurately. The success of these businesses is directly tied to their inventory management capabilities.

Key Features of Different Inventory Management Systems

| Feature | Perpetual Inventory System | Periodic Inventory System |

|---|---|---|

| Inventory Tracking | Real-time updates of inventory levels | Inventory counted periodically |

| Data Accuracy | High accuracy due to real-time updates | Potential for inaccuracies if not regularly updated |

| Cost Control | Helps track and control inventory costs in real-time | Cost analysis often done at the end of the period |

| Order Fulfillment | Streamlined order fulfillment processes | Order fulfillment processes can be less efficient |

| Stock Control | Helps maintain optimal stock levels | May not be as effective at maintaining optimal stock levels |

| Technology Dependence | Requires technology for real-time updates | Can be manual or use basic technology |

Core Functions of Inventory Management Systems

Inventory management systems are crucial for businesses of all sizes to efficiently track, manage, and control their stock levels. These systems automate tasks, providing real-time visibility into inventory, leading to improved forecasting, reduced costs, and enhanced customer satisfaction. Effective inventory management streamlines operations, optimizes resource allocation, and ultimately contributes to a company’s profitability.

Inventory management systems play a vital role in today’s dynamic business environment. They enable businesses to react swiftly to changing market demands, maintain optimal stock levels, and reduce the risk of stockouts or overstocking. By integrating with other business functions, these systems provide a holistic view of operations, allowing for informed decision-making and increased operational efficiency.

Order Processing

Order processing is a fundamental function of inventory management systems. It involves receiving, validating, and fulfilling customer orders. A robust order processing module ensures accurate order fulfillment, minimizes errors, and optimizes the entire order cycle. Efficient order processing directly impacts customer satisfaction and operational efficiency.

Inventory Tracking

Accurate inventory tracking is essential for maintaining optimal stock levels. Inventory management systems provide real-time visibility into inventory levels, locations, and movement. This allows businesses to identify discrepancies, predict future needs, and proactively address potential issues. Real-time tracking also enables businesses to optimize warehouse space and streamline logistics.

Reporting and Analysis

Comprehensive reporting and analysis are crucial for evaluating inventory performance and identifying areas for improvement. Inventory management systems generate various reports, including inventory turnover, stock levels, and profitability. These reports help businesses make data-driven decisions about inventory management strategies. Analysis of these reports aids in identifying trends, bottlenecks, and opportunities for optimization.

Inventory Forecasting and Demand Planning

Effective inventory forecasting is critical for minimizing stockouts and reducing excess inventory. Sophisticated forecasting models, often incorporated within inventory management systems, predict future demand based on historical data and market trends. Demand planning complements forecasting by identifying future demand patterns and adjusting inventory levels accordingly. Accurate forecasting and planning reduce the risk of stockouts and overstocking, ultimately leading to cost savings. For example, a retail store using sales data from previous seasons, promotions, and current market trends can effectively predict demand and optimize their inventory levels.

Integration with Other Business Functions

Inventory management systems integrate seamlessly with other business functions, such as sales and procurement. This integration ensures data consistency and facilitates efficient communication between departments. For instance, sales data feeds into the inventory management system to reflect real-time sales, while procurement data manages inventory replenishment based on established parameters. This integration ensures that all departments have access to the same, up-to-date inventory information.

Real-Time Data Updates and Reporting

Real-time data updates are essential for accurate inventory management. Systems with real-time functionality provide immediate updates on inventory levels, order status, and other relevant information. This enables proactive adjustments to stock levels and minimizes potential issues. Real-time reporting provides a continuous view of inventory performance, allowing businesses to react promptly to changing circumstances.

Modules/Features in a Typical Inventory Management System

| Module/Feature | Description |

|---|---|

| Order Management | Handles order placement, processing, and fulfillment. |

| Inventory Tracking | Monitors inventory levels, locations, and movement. |

| Inventory Forecasting | Predicts future demand based on historical data. |

| Demand Planning | Identifies future demand patterns and adjusts inventory levels. |

| Procurement Management | Manages the ordering and receiving of inventory. |

| Reporting and Analytics | Generates reports on inventory performance. |

| Sales Integration | Synchronizes inventory levels with sales data. |

| Warehouse Management | Optimizes warehouse operations and storage. |

Benefits of Implementing an Inventory Management System

Implementing an inventory management system offers a wide array of benefits for businesses of all sizes. These systems streamline processes, improve efficiency, and provide valuable insights, ultimately contributing to increased profitability and growth. By effectively managing inventory, businesses can optimize their resources, minimize waste, and respond more effectively to changing market demands.

An inventory management system provides a centralized platform for tracking inventory levels, movement, and associated costs. This centralized control allows for better forecasting, more accurate demand predictions, and improved decision-making regarding purchasing, storage, and sales strategies. By automating many tasks, businesses can free up valuable resources for more strategic initiatives.

Improved Efficiency and Productivity

An inventory management system enhances efficiency and productivity by automating various tasks, such as tracking stock levels, generating purchase orders, and managing shipping and receiving. This automation reduces manual errors, minimizes delays, and allows staff to focus on higher-value activities. Real-time visibility into inventory levels empowers businesses to respond swiftly to fluctuations in demand, preventing stockouts or overstocking. Reduced manual data entry also minimizes human error, ensuring data accuracy and reliability.

Reduced Costs

Implementing an inventory management system can significantly reduce operational costs. By optimizing stock levels, businesses can minimize holding costs associated with storage, insurance, and potential obsolescence. Effective inventory management systems also reduce the risk of stockouts, which can lead to lost sales and decreased customer satisfaction. The system can also help identify and eliminate discrepancies in inventory counts, reducing discrepancies and the need for costly recounts. Improved forecasting, reduced waste, and minimized ordering errors all contribute to lower overall costs.

Enhanced Decision-Making Capabilities

Inventory management systems provide valuable data and insights that support better decision-making. Real-time tracking of inventory movement, sales data, and demand patterns allows businesses to make informed decisions regarding pricing, purchasing, and production. Detailed reports and analytics enable businesses to identify trends, predict future needs, and adjust strategies accordingly. This data-driven approach allows businesses to make more strategic decisions, ultimately leading to improved profitability and growth.

Positive Impacts of Effective Inventory Control

Effective inventory control yields a multitude of positive impacts, contributing to overall business success. These benefits include:

- Reduced Stockouts and Overstocking: Accurate inventory tracking minimizes the risk of running out of essential products, leading to lost sales and dissatisfied customers. Conversely, it prevents overstocking, reducing holding costs and the risk of obsolescence.

- Improved Customer Satisfaction: Consistent availability of products and quick order fulfillment enhance customer satisfaction and loyalty. This is a critical factor in a competitive market.

- Minimized Holding Costs: By optimizing stock levels, businesses can minimize costs associated with storage, insurance, and potential spoilage or obsolescence. This directly translates to increased profitability.

- Increased Efficiency: Automation of tasks such as order processing and inventory tracking leads to significant time savings, freeing up employees for more strategic work. This boosts productivity.

- Enhanced Forecasting Accuracy: Data-driven insights into sales patterns, demand fluctuations, and inventory levels allow for more accurate forecasting, enabling businesses to anticipate future needs and make proactive decisions.

- Reduced Waste: Better inventory control minimizes waste from expired products, damaged goods, and unnecessary stockpiles.

- Improved Cash Flow: Reduced holding costs and minimized stockouts contribute to a more stable and predictable cash flow, essential for financial stability.

Challenges in Implementing Inventory Management Systems

Implementing an inventory management system (IMS) presents various hurdles for businesses, ranging from technical complexities to organizational adjustments. These challenges, while potentially daunting, can be overcome with careful planning, thorough preparation, and a proactive approach. Addressing these issues upfront minimizes disruption and ensures a smoother transition to the new system.

Common Business Challenges

Businesses often face difficulties integrating a new IMS with existing processes and software. Resistance to change from employees accustomed to established workflows can also hinder successful implementation. A lack of clear communication regarding the system’s benefits and functionalities can result in employee confusion and decreased adoption.

Technical Difficulties and Compatibility Issues

Compatibility problems between the new IMS and existing hardware and software systems are frequent. Legacy systems might not seamlessly integrate, requiring costly modifications or complete system overhauls. Data formats and protocols might not align, leading to inconsistencies and data loss. The selection of an IMS that adequately supports the specific needs and volume of a business is crucial to avoid technical bottlenecks. Failing to account for future growth can lead to system limitations as the company expands.

Importance of Proper Training

Comprehensive training programs are essential for maximizing user adoption and ensuring the system’s effective use. Employees must be proficient in navigating the system’s interface, utilizing its features, and interpreting the generated reports. Training should be tailored to the specific roles and responsibilities of each user, ensuring that they understand how to perform their tasks efficiently within the new system. A well-structured training program promotes user confidence and reduces the learning curve.

Data Accuracy and Integrity

Data accuracy and integrity are critical components of an effective IMS. Inaccurate data can lead to incorrect inventory levels, flawed reports, and ultimately, financial discrepancies. A well-defined data entry process, combined with regular data validation checks, is essential for maintaining data quality. Implementing procedures for data cleansing and reconciliation can identify and correct errors before they impact operational decisions.

Methods to Overcome Data Migration Challenges

Migrating existing data to the new IMS can be a complex process. A detailed data migration plan, outlining the steps, timelines, and responsibilities, is vital for success. Using data transformation tools to convert data into the required format can help streamline the process. Testing the migrated data thoroughly before fully deploying the system is crucial to identify and rectify any errors early. Backup and recovery procedures are critical to mitigate the risk of data loss during migration.

Comparison of Inventory Management System Implementations

| Implementation Approach | Pros | Cons |

|---|---|---|

| Phased Rollout | Reduced risk, gradual adaptation, allows for feedback | Longer implementation time, potential for inconsistencies between phases |

| Big Bang Approach | Faster implementation, quicker return on investment | Higher risk of errors, potential for disruption to operations |

| Hybrid Approach | Combines elements of both phased and big bang approaches | Requires careful planning and coordination |

This table provides a comparative overview of different implementation approaches. The best approach depends on the specific circumstances of the business, including its size, resources, and existing infrastructure.

Choosing the Right Inventory Management System

Selecting the appropriate inventory management system is crucial for businesses of all sizes. A well-chosen system can streamline operations, optimize inventory levels, and enhance profitability. Conversely, a poorly chosen system can lead to inefficiencies, increased costs, and lost sales opportunities. Careful consideration of various factors is essential to ensure the chosen system aligns with current and future business needs.

Factors to Consider When Selecting an Inventory Management System

Choosing the right inventory management system requires a thorough evaluation of several key factors. Understanding these factors ensures that the chosen system effectively supports the business’s operational needs and future growth trajectory.

- Business Size and Structure: Small businesses may benefit from cloud-based systems offering user-friendly interfaces and affordable pricing. Larger enterprises with complex operations may require more robust systems with advanced features, such as warehouse management integrations or enterprise resource planning (ERP) connections. A system should be scalable to accommodate future growth. For example, a rapidly expanding e-commerce company will need a system capable of handling increasing order volumes and inventory tracking.

- Industry Requirements: Certain industries have specific inventory management needs. For example, a pharmaceutical company will require systems adhering to strict regulatory guidelines and sophisticated tracking for controlled substances. A food distributor needs systems capable of handling temperature-sensitive products. Matching the system’s features to the industry’s particularities is paramount.

- System Features and Functionalities: Evaluating the specific features and functionalities is essential. Key features to consider include inventory tracking, order management, reporting capabilities, integration with other business systems (e.g., accounting software), and user-friendly interface. The system should effectively address the company’s unique inventory needs.

- Scalability and Future Growth: The chosen system should be scalable to accommodate future growth in sales, inventory volume, and customer base. An overly restrictive system may become a bottleneck as the business expands. Consider a system’s capacity to handle increasing data volumes and transactions without significant performance degradation.

Pricing Models for Inventory Management Systems

Various pricing models exist for inventory management systems. Understanding these models is vital for budgetary planning and selecting a suitable system.

- Subscription-Based Models: These models often involve monthly or annual fees, offering predictable costs. The pricing is typically based on features utilized, number of users, or data storage requirements. For example, a basic subscription might be suitable for small businesses with limited inventory needs, while a premium subscription might be necessary for larger enterprises requiring extensive functionalities.

- Per-Transaction Models: Some systems charge based on the number of transactions processed, like orders fulfilled or items scanned. This model can be advantageous for businesses with fluctuating transaction volumes. However, the cost can become unpredictable for businesses experiencing high transaction peaks.

- Custom Development Models: Businesses with unique or highly specialized inventory needs may require custom-developed systems. The cost for this option can be substantial, but it ensures the system perfectly fits the business’s requirements. This approach is generally best for companies with very specific needs or very large volumes of unique inventory items.

Evaluating Inventory Management System Vendors

Careful vendor evaluation is critical to ensure the chosen system aligns with business requirements. The following table Artikels factors to consider.

| Factor | Description |

|---|---|

| Reputation and Experience | Evaluate the vendor’s track record, industry recognition, and experience in handling similar businesses. Look for positive customer testimonials and case studies. |

| System Stability and Performance | Assess the system’s reliability, security, and performance. Consider factors such as uptime, response time, and data security features. |

| Customer Support and Training | Evaluate the quality of customer support offered by the vendor. Look for prompt response times, clear documentation, and user training materials. |

| Integration Capabilities | Assess the system’s ability to integrate with existing business software (e.g., accounting software, CRM systems). |

| Vendor Financial Stability | Consider the financial health of the vendor to ensure long-term support and maintenance of the system. |

Inventory Management System Design Considerations

A well-designed inventory management system is crucial for efficient operations. It not only streamlines processes but also enhances user experience, ensuring data accuracy and security. A robust system design lays the foundation for long-term success, reducing errors and improving overall productivity.

Importance of System Design and User Experience

Effective inventory management relies heavily on a system that is user-friendly and intuitive. A poorly designed system can lead to errors, frustration among users, and ultimately, reduced efficiency. A well-designed system, on the other hand, promotes accuracy, reduces manual intervention, and allows users to focus on core business functions. A good user experience fosters user adoption and reduces the learning curve for new employees.

User Interface (UI) and User Experience (UX) Principles

User-centric design is paramount in inventory management systems. Clear, concise, and visually appealing interfaces are essential for efficient data entry and retrieval. Intuitive navigation, easily accessible functionalities, and consistent design elements are key components of a good user experience. This ensures that users can quickly learn the system and perform tasks effectively. Employing a consistent color scheme and typography, coupled with clear labels and tooltips, enhances the usability of the system.

System Security and Data Protection

Protecting sensitive inventory data is paramount. Implementing robust security measures, such as user authentication, access controls, and data encryption, is critical. Regular security audits and updates are essential to mitigate risks and ensure data integrity. These measures safeguard against unauthorized access and data breaches, maintaining confidentiality and trust.

Ensuring Data Integrity and Accuracy

Maintaining data accuracy is vital for reliable inventory management. Implementing validation rules, data checks, and error handling mechanisms ensures data quality. Data entry should be automated where possible to minimize manual intervention and associated errors. Regular data audits and reconciliation procedures further ensure the accuracy of inventory records. Real-time updates and automated alerts can aid in quick identification of discrepancies.

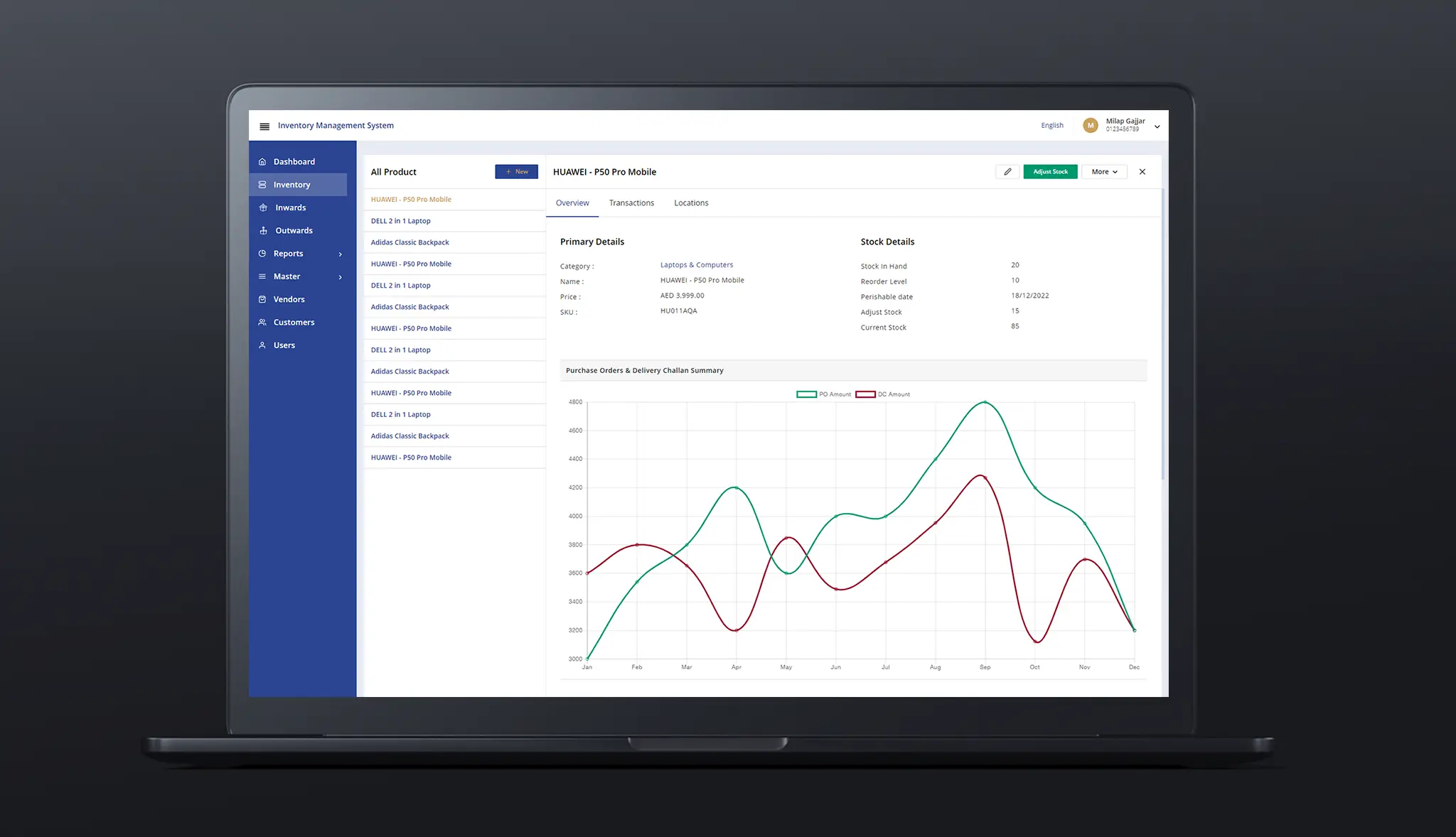

User-Friendly Inventory Management System Dashboard Design

A well-designed dashboard provides a clear overview of key inventory metrics. The dashboard should display real-time data on stock levels, order status, and key performance indicators (KPIs). Visualizations, such as charts and graphs, are effective in conveying information quickly and efficiently. Interactive elements, allowing users to drill down into specific data points, facilitate in-depth analysis.

- Real-time Inventory Levels: Displaying current stock levels for each item in a clear and easily readable format, with the ability to filter by category or location.

- Order Status Tracking: A concise view of pending orders, shipments, and deliveries, providing updates on each order’s progress.

- Key Performance Indicators (KPIs): Displaying critical metrics such as inventory turnover rate, storage costs, and order fulfillment time.

- Customizable Views: Allowing users to tailor the dashboard to their specific needs and preferences, displaying only the information they require.

- Alert System: Implementing an alert system to notify users of low stock levels, impending order deadlines, or other critical events.

Comparison of Different User Interface Designs

| Design Type | Strengths | Weaknesses |

|---|---|---|

| Tabular Design | Simple, easy to understand, suitable for basic data display. | Limited visualization capabilities, can become cluttered with large datasets. |

| Graphical Design | Effective for visualizing trends and patterns, allows for quick data interpretation. | Can be complex to implement, might require more technical expertise. |

| Combined Design | Combines the strengths of both tabular and graphical designs, providing a comprehensive overview. | Potentially more complex to develop and maintain. |

Integrating Inventory Management Systems with Other Business Processes

Integrating inventory management systems with other core business functions like sales and accounting is crucial for a streamlined and efficient operation. This integration ensures data consistency and enables real-time visibility across the entire organization. A well-integrated system provides valuable insights, allowing businesses to make informed decisions and optimize resource allocation.

Seamless Data Exchange Between Systems

Effective data exchange between inventory management systems and other business functions is essential for accurate reporting and decision-making. Without seamless data flow, discrepancies and inefficiencies can arise. For instance, inaccurate inventory levels reported to sales can lead to missed opportunities or stockouts, while incorrect accounting entries can result in financial misstatements. A well-designed system ensures that data flows accurately and consistently between the inventory management system and other systems.

Optimizing Workflows for Efficient Data Flow

Streamlined workflows are paramount for efficient data flow. This includes automating processes where possible, such as automatically updating sales orders with inventory availability. Integration should also consider real-time updates. Real-time inventory tracking ensures that sales orders are updated immediately when stock levels change, preventing order fulfillment issues. Implementing robust data validation rules helps prevent errors and maintain data integrity.

Examples of Successful Integrations

Many businesses have successfully integrated their inventory management systems with sales and accounting. A retail company, for example, might integrate their inventory management system with their point-of-sale (POS) system to automatically update inventory levels as items are sold. This real-time visibility allows for proactive inventory replenishment and prevents stockouts. Similarly, a manufacturing company can integrate their inventory management system with their accounting software to automatically generate invoices and track costs associated with inventory.

Data Flow Diagram: Inventory Management System and Other Business Systems

A diagram depicting the data flow would show a central inventory management system (IMS) connected to other business systems, including sales and accounting. The IMS receives data from various sources, including sales orders and production updates. It updates its inventory levels based on these inputs and, in turn, provides real-time data on stock availability to sales and production teams. This data flows to the accounting system for cost tracking and revenue recognition. The diagram highlights the two-way flow of information, emphasizing the reciprocal nature of the integration.

| Data Source | Inventory Management System (IMS) | Data Destination |

|---|---|---|

| Sales Orders | Updates inventory levels, generates picking lists | Sales Team, Warehouse |

| Production Updates | Adjusts inventory levels based on finished goods | Accounting, Warehouse |

| Warehouse Stock Transfers | Tracks and updates inventory | Inventory Reports, Accounting |

| Accounting Transactions | Updates cost accounting, tracks inventory valuation | Financial Reports, Management Reports |

Best Practices for Inventory Management Systems

Optimizing inventory management is crucial for businesses to maintain profitability and customer satisfaction. Effective systems ensure products are available when needed, reducing stockouts and minimizing holding costs. Implementing best practices leads to streamlined processes, accurate forecasting, and improved inventory turnover.

Optimizing Inventory Management

Best practices for inventory management encompass a wide range of strategies aimed at maximizing efficiency and minimizing waste. These strategies involve understanding demand patterns, forecasting accurately, and maintaining optimal stock levels. Careful analysis of historical sales data, market trends, and seasonal variations is essential for effective forecasting. Implementing robust inventory tracking systems is critical to ensure accurate records of stock levels, movement, and locations.

- Demand Forecasting: Accurate demand forecasting is fundamental for optimizing inventory levels. This involves analyzing historical sales data, identifying trends, and considering external factors like seasonality and promotions. Sophisticated forecasting models, such as time series analysis and machine learning algorithms, can enhance accuracy. Using data from previous sales, promotions, and market trends can help businesses predict future demand and adjust inventory levels accordingly.

- Safety Stock Management: Establishing appropriate safety stock levels is vital to mitigate the risk of stockouts. This involves considering lead times, demand variability, and potential disruptions. Safety stock should be calculated based on the probability of demand exceeding supply during lead times. A company might maintain a 10% buffer above expected demand to account for unexpected spikes.

- ABC Analysis: Classifying inventory items based on their value and importance is crucial. ABC analysis categorizes items into A (high-value), B (medium-value), and C (low-value) groups. This allows businesses to focus their efforts on managing high-value items effectively and optimizing resource allocation.

- Just-in-Time (JIT) Inventory: Implementing a JIT inventory system can reduce holding costs and storage space. This strategy involves ordering and receiving inventory only when it is needed for production or sale. This approach requires precise demand forecasting and reliable supply chains.

Efficient Order Fulfillment and Delivery

Streamlined order fulfillment and delivery processes are essential for customer satisfaction and operational efficiency. This involves optimizing warehouse operations, managing order picking and packing, and ensuring timely delivery. Implementing an effective warehouse management system (WMS) can significantly improve efficiency.

- Order Picking Optimization: Implementing efficient order picking strategies, such as zone picking or batch picking, can reduce order fulfillment times. These strategies aim to minimize travel time within the warehouse and optimize picking routes.

- Delivery Route Optimization: Optimizing delivery routes through the use of route planning software can reduce transportation costs and improve delivery times. Factors such as traffic conditions, delivery windows, and driver availability should be considered.

- Real-time Tracking: Real-time tracking of orders provides visibility into the status of each order throughout the fulfillment process. This allows customers to monitor their shipments and businesses to identify and resolve potential delays.

Automation in Inventory Control

Automation plays a critical role in improving inventory control by reducing manual errors, increasing efficiency, and providing real-time data. This includes using automated storage and retrieval systems (AS/RS), automated guided vehicles (AGVs), and inventory management software.

- Automated Storage and Retrieval Systems (AS/RS): AS/RS are automated systems that store and retrieve inventory items. These systems improve efficiency by optimizing space utilization, reducing manual handling, and ensuring accuracy.

- Inventory Management Software: Implementing an advanced inventory management system allows for real-time tracking of inventory levels, order fulfillment, and other key metrics. This enables businesses to make informed decisions about stock levels and optimize operations.

Regular System Maintenance and Updates

Regular system maintenance and updates are critical for ensuring the smooth functioning of inventory management systems. This involves addressing bugs, improving performance, and incorporating new features. This can involve scheduled maintenance, software updates, and security patches.

- System Security: Maintaining robust security measures is paramount to prevent unauthorized access and data breaches. Implementing strong passwords, access controls, and regular security audits are essential.

- Software Updates: Keeping software up-to-date is essential to benefit from new features, performance enhancements, and security patches. Regular updates help prevent vulnerabilities and ensure the system remains reliable.

Streamlined Inventory Management Process Flowchart

[A visual flowchart illustrating the steps involved in a streamlined inventory management process would be placed here. The flowchart would depict the flow from receiving inventory to order fulfillment and delivery, highlighting key stages and decision points. A detailed description of the process would be included.]

Last Word

So, there you have it—a deep dive into the world of inventory management systems. From understanding the core functions to navigating potential challenges and choosing the perfect system, we’ve covered it all. Remember, a well-managed inventory system is key to success in any industry. So, embrace the power of organization and watch your business thrive!